Unlocking the Potential of 219x16 Steel: A Comprehensive Guide to Its Properties and Applications

Introduction to 219x16 Steel

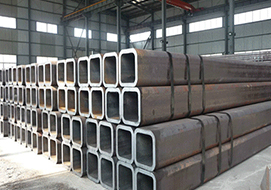

219x16 steel is a specialized alloy known for its exceptional strength and durability, making it a preferred choice in sectors such as construction, automotive, and heavy machinery. This steel grade combines specific chemical compositions to achieve superior mechanical properties, including high tensile strength and resistance to wear and corrosion. Understanding its core attributes is essential for engineers and manufacturers seeking reliable materials for critical projects.

Key Properties and Benefits

The primary advantage of 219x16 steel lies in its robust mechanical performance. With a composition that includes elements like chromium and molybdenum, it offers enhanced hardness and toughness, allowing it to withstand extreme pressures and temperatures. Additionally, its excellent weldability and machinability facilitate easy fabrication, reducing production costs and time. These properties make it ideal for applications where safety and longevity are paramount, such as in structural supports or industrial equipment.

Common Applications in Industry

In real-world scenarios, 219x16 steel is extensively used in the construction of bridges, high-rise buildings, and pipelines due to its load-bearing capacity. For instance, in the automotive industry, it is employed in chassis components and engine parts to enhance vehicle safety and efficiency. Moreover, its corrosion resistance makes it suitable for marine environments, where exposure to saltwater can degrade lesser materials. By leveraging these applications, businesses can achieve improved performance and reduced maintenance needs.

Expert Tips for Selection and Use

When selecting 219x16 steel, consider factors such as the intended environment and stress levels. For optimal results, ensure proper heat treatment processes are followed to maximize its strength. It's also advisable to consult with material specialists to match the steel grade with specific project requirements. Regular inspections and maintenance can further extend its lifespan, preventing premature failures and ensuring compliance with industry standards.

Frequently Asked Questions

What are the main differences between 219x16 steel and other steel grades?

219x16 steel is distinguished by its specific alloying elements, which provide higher strength and better corrosion resistance compared to standard carbon steels. It is often used in more demanding applications where these properties are critical.

How can I ensure the quality of 219x16 steel in my projects?

To ensure quality, source materials from reputable suppliers who provide certification and testing reports. Additionally, conduct regular quality checks during fabrication and installation to verify compliance with specifications.

Is 219x16 steel suitable for high-temperature environments?

Yes, due to its alloy composition, 219x16 steel maintains its structural integrity at elevated temperatures, making it suitable for applications like boilers and heat exchangers. However, always consult technical data sheets for specific temperature limits.