Steel Plate: The Backbone of Modern Construction and Manufacturing

Introduction to Steel Plates

Steel plates, often referred to as steel sheets in industrial contexts, are flat pieces of steel that serve as fundamental building blocks in numerous sectors. They are manufactured through processes like hot rolling or cold rolling, which determine their thickness and properties. Common types include carbon steel plates, stainless steel plates, and alloy steel plates, each tailored for specific uses. For instance, carbon steel plates are widely used in structural applications due to their high strength and cost-effectiveness, while stainless steel plates offer excellent corrosion resistance, making them ideal for food processing or marine environments. Understanding these basics is crucial for selecting the right material for your project, as it can impact safety, longevity, and overall performance.

Applications in Construction and Engineering

In the construction industry, steel plates play a vital role in creating robust frameworks for buildings, bridges, and infrastructure. They are often used in foundations and beams to distribute loads evenly and resist environmental stresses like earthquakes or high winds. For example, in skyscraper construction, thick steel plates form the core support systems, ensuring stability over decades. Beyond buildings, they are essential in civil engineering projects such as dams and tunnels, where their ability to withstand pressure and corrosion is paramount. Additionally, in the automotive sector, steel plates are used in vehicle chassis and body panels, providing crash resistance and fuel efficiency. By choosing the appropriate grade and thickness, engineers can optimize designs for both safety and sustainability, reducing material waste and enhancing recyclability.

Benefits and Advantages

The primary benefits of steel plates include their exceptional strength-to-weight ratio, which allows for lighter structures without compromising integrity. This makes them a preferred choice in aerospace and shipbuilding, where every kilogram saved translates to improved efficiency. Moreover, steel plates are highly durable and resistant to wear, requiring minimal maintenance over their lifespan. They also support sustainable practices, as steel is one of the most recycled materials globally, with recycling rates exceeding 90% in many regions. From an economic perspective, the versatility of steel plates enables cost savings through standardized production and easy fabrication techniques like welding or cutting. For businesses, this means faster project completion and reduced downtime, ultimately boosting profitability and competitiveness in the market.

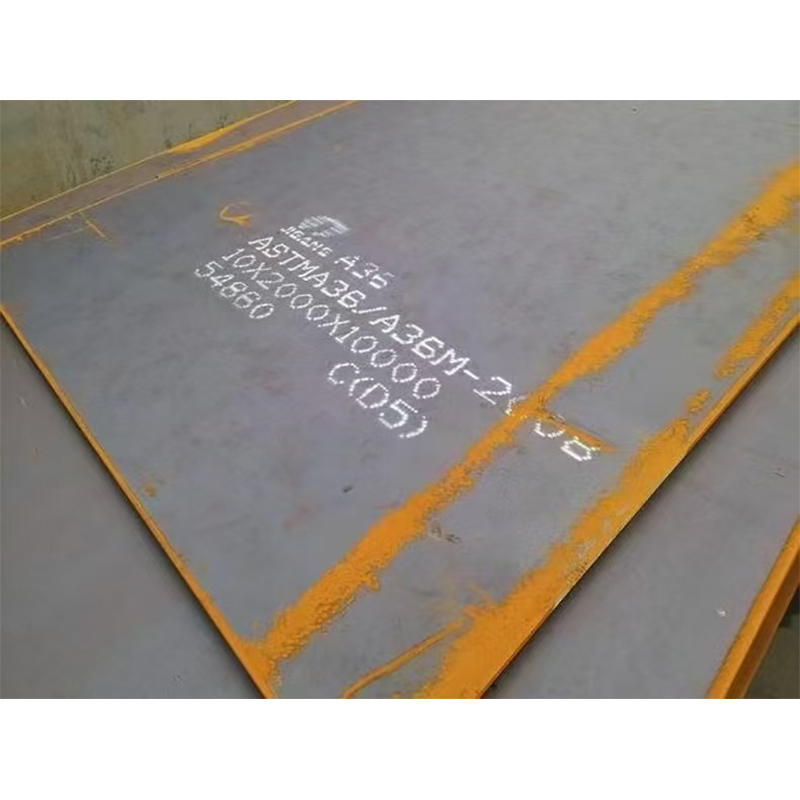

Selection and Best Practices

When selecting steel plates, it's important to consider factors such as thickness, grade, and coating. Thicker plates, for instance, are suited for heavy-duty applications like industrial machinery, while thinner ones might be used in consumer goods. Grades like ASTM A36 for general purposes or A572 for high-strength needs should match the environmental conditions, such as exposure to moisture or chemicals. Coating options, such as galvanizing or painting, can enhance corrosion resistance and extend service life. In practice, conducting material tests and consulting with suppliers can prevent common issues like premature failure. Additionally, adhering to industry standards and regulations ensures compliance and safety. For example, in welding, using proper techniques and filler materials avoids weaknesses in joints, which is critical in load-bearing structures.

Common Questions

What are the main types of steel plates and their differences?

The main types include carbon steel, stainless steel, and alloy steel plates. Carbon steel is strong and economical, ideal for construction; stainless steel resists corrosion, perfect for harsh environments; and alloy steel offers enhanced properties like hardness for specialized machinery.

How do I choose the right thickness for a steel plate?

Thickness selection depends on the application's load requirements. For light structures, 1-3 mm may suffice, while heavy industrial uses might need 10 mm or more. Consult engineering guidelines or a professional to ensure optimal performance and safety.

Can steel plates be recycled, and how does it benefit the environment?

Yes, steel plates are highly recyclable. Recycling reduces energy consumption by up to 75% compared to producing new steel, lowers greenhouse gas emissions, and conserves natural resources, making it an eco-friendly choice.