Square Tubes: The Cornerstone of Modern Construction and Manufacturing

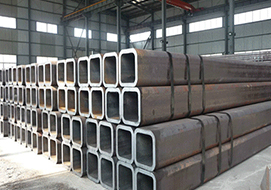

Introduction to Square Tubes

Square tubes, or square hollow sections (SHS), are metal profiles with a square cross-section and hollow interior. They are typically made from materials like steel, aluminum, or stainless steel, offering a balance of strength, durability, and lightweight design. These tubes are manufactured through processes such as hot rolling, cold forming, or welding, ensuring precise dimensions and smooth surfaces. Their geometric shape provides excellent load-bearing capacity and resistance to bending, making them ideal for structural applications. In modern industries, square tubes have become indispensable due to their versatility and cost-effectiveness.

Key Properties and Advantages

Square tubes boast several key properties that set them apart from other structural shapes. First, their high strength-to-weight ratio allows for robust construction without excessive material use, reducing costs and environmental impact. The hollow interior minimizes weight while maintaining rigidity, which is crucial for applications like building frames or machinery supports. Additionally, square tubes offer superior torsional resistance compared to round tubes, making them more stable under twisting forces. They are also easy to fabricate, as their flat surfaces simplify cutting, welding, and joining processes. From a durability perspective, materials like galvanized steel or coated aluminum provide corrosion resistance, extending the lifespan of structures in harsh environments.

Common Applications in Various Industries

Square tubes find applications across a wide range of industries, demonstrating their adaptability. In construction, they are used for building frameworks, bridges, and scaffolding, providing reliable support for large structures. The automotive sector employs them in chassis and roll cages, where strength and safety are paramount. In manufacturing, square tubes serve as components in machinery, conveyor systems, and storage racks, enhancing operational efficiency. For DIY projects and furniture making, they offer a sleek, modern aesthetic for items like tables, shelves, and outdoor fixtures. Moreover, in infrastructure projects such as pipelines or fencing, square tubes ensure stability and longevity. Their versatility extends to artistic installations, where their clean lines and customizable sizes allow for creative designs.

Selection and Installation Tips

Choosing the right square tube involves considering factors like material, size, and wall thickness. For heavy-duty applications, steel square tubes with thicker walls are recommended, as they can withstand higher loads. In contrast, aluminum tubes are lighter and more corrosion-resistant, suitable for outdoor or marine environments. When selecting sizes, measure the required dimensions carefully; common standards include metric or imperial units, with wall thicknesses ranging from thin to thick gauges. During installation, ensure proper alignment and use appropriate welding or bolting techniques to maintain structural integrity. It's also advisable to apply protective coatings or paints to prevent rust and enhance appearance. For safety, always follow industry guidelines and consult professionals for complex projects.

Common Questions

What are the main differences between square tubes and round tubes?

Square tubes have flat surfaces and right-angle corners, offering better load distribution and ease of joining, while round tubes are more resistant to external pressure and have a smoother flow for fluids. The choice depends on the specific application, such as structural support versus piping.

How do I determine the appropriate wall thickness for a square tube?

Wall thickness should be based on the expected load and environmental conditions. Thicker walls provide higher strength for heavy loads, but increase weight and cost. Consult engineering tables or professionals to match thickness with requirements like stress tolerance and corrosion resistance.

Can square tubes be recycled?

Yes, most square tubes made from metals like steel or aluminum are highly recyclable. Recycling reduces waste and conserves resources, making them an eco-friendly option. Always check local recycling guidelines for proper disposal methods.