The Versatile World of 200x300 Rectangular Steel Tubes: A Comprehensive Guide

Introduction to 200x300 Rectangular Steel Tubes

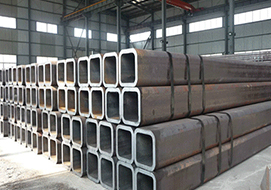

200x300 rectangular steel tubes, often referred to as rectangular hollow sections (RHS) in engineering contexts, are a type of structural steel profile with dimensions of 200 millimeters in width and 300 millimeters in height. These tubes are manufactured through processes like hot-rolling or cold-forming, resulting in a hollow cross-section that provides an excellent strength-to-weight ratio. Commonly made from materials such as carbon steel or stainless steel, they are widely used in various industries due to their versatility and load-bearing capabilities. Understanding their properties is key to leveraging their full potential in projects ranging from small-scale fabrication to large infrastructure developments.

Applications in Construction and Engineering

The applications of 200x300 rectangular steel tubes are extensive and diverse. In construction, they serve as primary structural elements in buildings, bridges, and frameworks, where their rectangular shape allows for efficient connection and integration with other components. For example, in industrial warehouses, these tubes form the backbone of support columns and beams, ensuring stability under heavy loads. In civil engineering, they are used in bridge girders and trusses, contributing to the overall integrity and safety of transportation networks. Beyond construction, they find use in manufacturing equipment, such as conveyor systems and machinery frames, where their rigidity and resistance to deformation are crucial. Their adaptability also extends to architectural designs, where they can be incorporated into modern façades or interior structures for aesthetic and functional purposes.

Benefits and Advantages

One of the primary benefits of 200x300 rectangular steel tubes is their high strength and durability. The hollow design reduces material weight without compromising structural integrity, making them cost-effective for large-scale projects. Additionally, their uniform shape facilitates easy welding, bolting, and fabrication, which streamlines assembly processes and reduces labor costs. From a sustainability perspective, steel is recyclable, and these tubes often have a long service life with minimal maintenance, contributing to eco-friendly practices. In terms of safety, their resistance to fire, corrosion (when properly coated or made from stainless steel), and environmental stresses ensures reliable performance in harsh conditions. This combination of factors makes them a preferred choice for engineers and builders seeking efficient and resilient solutions.

Practical Considerations for Selection and Use

When selecting 200x300 rectangular steel tubes for a project, several factors must be considered to ensure optimal performance. First, assess the material grade and thickness, as these influence load capacity and corrosion resistance. For instance, in marine environments, stainless steel variants may be necessary to prevent rust. Second, consider the manufacturing process: hot-rolled tubes are generally stronger but may have surface imperfections, while cold-formed tubes offer smoother finishes and tighter tolerances. Third, evaluate the connection methods, such as welding or mechanical fasteners, to ensure compatibility with other structural elements. It's also important to account for factors like thermal expansion, which can affect dimensional stability over time. Consulting with suppliers and adhering to industry standards, such as ASTM or EN specifications, can help in making informed decisions and avoiding common pitfalls.

Common Questions

What are the typical uses of 200x300 rectangular steel tubes in residential construction?

In residential construction, 200x300 rectangular steel tubes are often used for support beams, columns, and framing in multi-story buildings. They provide robust support for floors and roofs, especially in modern designs that require open spaces without internal walls. Additionally, they can be employed in outdoor structures like pergolas or carports, where their durability withstands weather elements.

How do I determine the right thickness for my project?

The appropriate thickness depends on the load requirements and environmental conditions. For light-duty applications, such as decorative elements, thinner tubes may suffice. However, for heavy structural loads, thicker walls are necessary to prevent buckling or deformation. Consulting engineering calculations or a structural engineer is recommended to ensure safety and compliance with building codes.

Are there any maintenance tips for prolonging the life of these tubes?

To extend the lifespan of 200x300 rectangular steel tubes, regular inspections for corrosion or damage are essential. Applying protective coatings, such as paint or galvanization, can prevent rust in exposed environments. In high-moisture areas, using stainless steel variants or ensuring proper drainage around structures can minimize deterioration. Cleaning with mild detergents and avoiding abrasive materials during maintenance also helps preserve their integrity.